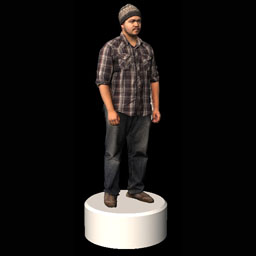

Scanning

The Process

Photogrammetry scans all start the same. Numerous photos are taken of an object from all angles. These images are then inputed into a computer where a program detects the same surface features of the object in a number of the photographs and then is able to create the original 3D shape. The photographs can be taken with one camera over a period of time or, as in the case of this rig, numerous cameras take all the shots at the exact same moment and can freeze the action. Depending on the output required from the scan, the processing and clean-up of the data can be very different.

1. Scanning

The scanning rig when not being used is in its default configuration of scanning a human form. If something the size of a human needs to be scan, very little prep needs to be done and the scan can be accomplished in an hour or so. Objects that are larger or smaller than a human form will require cameras to be moved. Surfaces that are reflective, very dark, or very white, also require special setups. Re configuring the rig can take as long a couple of days.

2. Processing

Once the scan is completed, the images are brought into the processing computer where the software aligns all the images, finds common surface information, and plots the original 3D shape. This is a multi-step process and depending on a number of variables can take from 1-12 hours to process. This process has been scripted so that they can be run in a Queue overnight.

3. Clean-up

Most times, the scan needs to be used in a visualization or printed. The processed scan needs to be cleaned up and prepped. This can be a very time-consuming process depending on the output requirements.