Blog

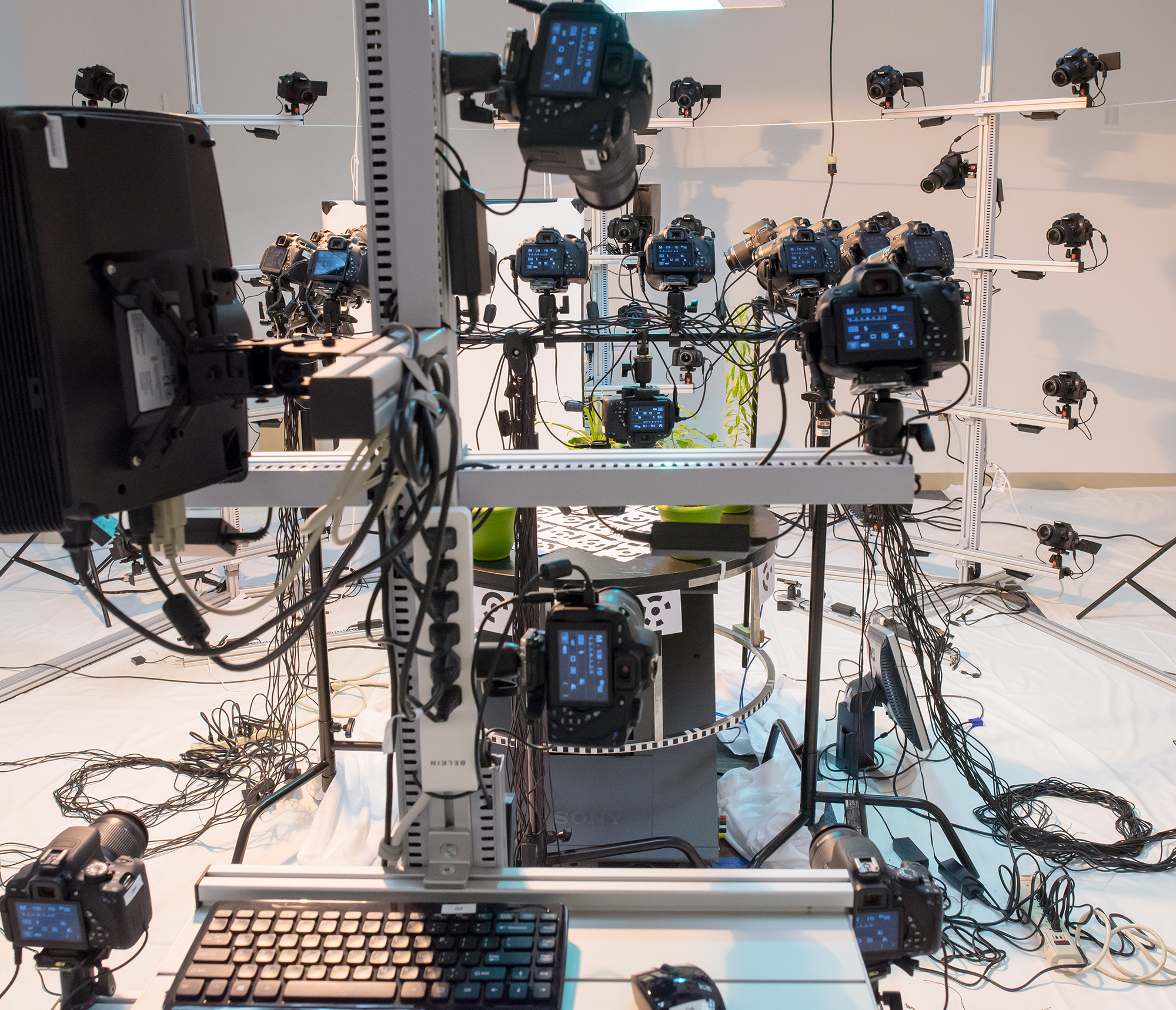

Custom Configuring the Scanning Rig for Specialized Research

August 3, 2016

Professor Lynn Cazabon's project, Plantelligence, is requiring extensive customization of the scanning rig. More cameras have been added to better scan the intricate detail of plants. Also, the plants need to be scanned in time-lapse, recording their growth over 2-3 months. To read more about Lynn's project, check out the Projects page.

However, not only is Professor Cazabon's project innovative, but the configuring of the rig to automatically handle time-lapse, extra cameras, control of grow lights, robotic registering turntable and multiple plants is a research project in itself. Mark Murnane is an Computer Science and Electrical Engineering undergraduate who is doing the innovative hardware and software configuration for this effort. Mark is in his senior year at UMBC and spent last year interning with Direct Dimensions on building this rig. This year he is overseeing its use, upgrades, and specialization requirements.

3D Model of Ribbon Cutting Ceremony

December 16, 2016

Checkout the finished and prepped model of the ribbon cutting ceremony. This scan was completed just as the ribbon as cut. Use you mouse to rotate around Michael Rapheal and Freeman Hrabowski. Thanks to everyone at Direct Dimensions for building the rig and creating this scan.

To read more about the ribbon cutting ceremony, read our previous blog post.

3D Scanning Room opens with a 90-camera flash

December 14, 2015

Shared from UMBC NEWS

UMBC’s Imaging Research Center (IRC) has debuted the 3D Scanning Room, featuring new software that allows 3D models to be created by combining dozens of 2D photographs. A ribbon-cutting event and brief remarks from President Freeman Hrabowski and Vice President of Research Karl Steiner were held on Tuesday, December 8.

The 3D Scanning Room features 90 digital single-lens reflex (DSLR) cameras that are set up in a circular formation around a space where people or objects are positioned for 2D photographs. The cameras take simultaneous photos, looking for features like textures and edges that reflect light.

Once the photos are captured, they are processed through special software called Agisoft Photoscan, to create a virtual 3D model of the subject. It takes between four and six hours for the software to render a clear and detailed 3D image from the approximately 90 photos that are taken, but a rough depiction is available within an hour of the photos being snapped.

President Hrabowski said that the technology in the 3D Scanning Room is expanding the possibilities for UMBC researchers, thinkers, and artists. “This technology connects faculty across disciplines, and is fascinating because it goes across all UMBC colleges and departments,” he said.

Steiner described the 3D Scanning Room as a “three-legged stool”—a reliable, stable, easy to use system to create 3D models through the three steps of visualization, scanning and fabrication. Fabrication refers to the actual cutting or layering of the data to create a tangible 3D model.

The subjects being photographed do not need to be stationary. The cameras can capture people or objects in motion, explained Don Engel, assistant vice president for research at UMBC.

Direct Dimensions, Inc., a Maryland-based company specializing in 3D imaging for the medical, consumer and military industries, worked with UMBC’s Marc Olano, associate professor of computer science and electrical engineering (CSEE) and principal investigator (PI), and Dan Bailey, director of the IRC and co-PI, to create the 3D Scanning space. The space was funded through a $180,000 grant from the National Science Foundation.